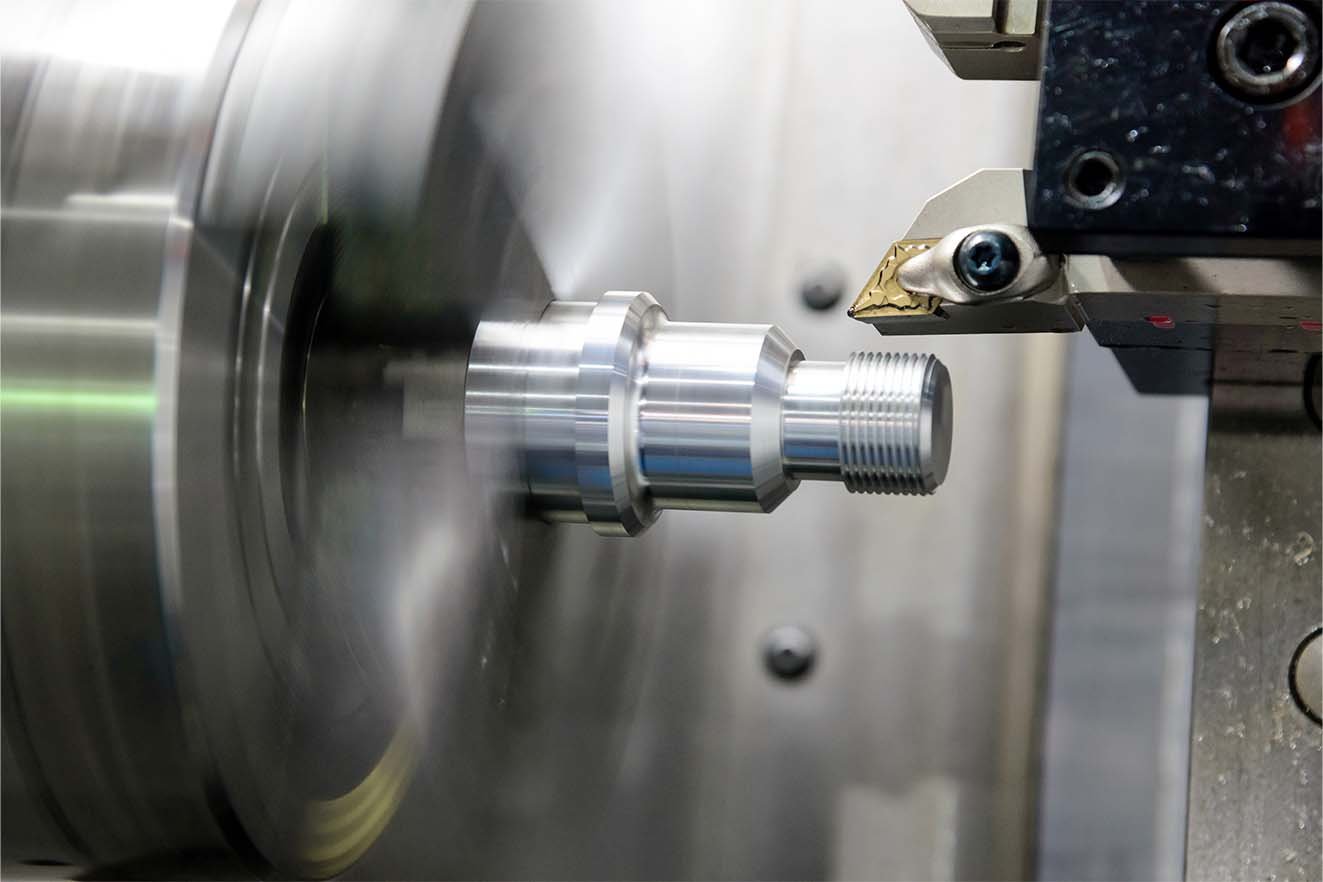

what Is a Lathe Machine?

Lathe machines are fundamental in metalworking and woodworking industries for shaping, cutting, drilling, and sanding materials. They operate by rotating a workpiece against various cutting tools to remove material symmetrically, creating cylindrical shapes or intricate designs. The turning process involves the use of specialized tools known as lathe-turning tools.

Understanding Lathe-Turning Tools

Lathe-turning tools are essential components of lathe machines, designed to shape and cut materials effectively. They come in various shapes, sizes, and materials, each serving specific purposes in the turning process. Here’s a breakdown of common lathe-turning tools and their applications:

| Tool Name | Description | Application |

| 1. Turning Tool | Features a cutting edge for removing material along the length of the workpiece. | Ideal for creating cylindrical shapes, facing, and profiling workpieces. |

| 2. Boring Bar | Used to enlarge existing holes or create internal features with precision. | Essential for boring operations, such as creating precise diameters or cavities within the workpiece. |

| 3. Parting Tool | Designed to cut off sections of the workpiece, separating them from the main stock. | Commonly used for creating grooves, parting off workpieces, or forming shoulders. |

| 4. Thread Cutting Tool | Utilized to create threads on cylindrical surfaces. | Essential for producing threads of various pitches and depths on workpieces. |

| 5. Knurling Tool | Equipped with a patterned wheel to create a knurled texture on the workpiece. | Used for enhancing grip or aesthetic appeal on cylindrical surfaces. |

| 6. Facing Tool | Designed to create flat surfaces perpendicular to the rotational axis. | Ideal for squaring off the ends of cylindrical workpieces or removing excess material. |

Art of Machining: Exploring the Depths of Milling and Turning

Applications of Lathe Machines and Turning Tools

Lathe machines, coupled with turning tools, find applications across numerous industries, including:

- Automotive Industry: Used for manufacturing engine components, shafts, gears, and other precision parts.

- Aerospace Industry: Essential for crafting intricate components like turbine blades, engine parts, and landing gear components.

- Medical Sector: Utilized in producing implants, surgical instruments, and prosthetic limbs with precision.

- Woodworking Industry: Employed for crafting furniture components, decorative items, and architectural elements.

- Metal Fabrication: Crucial for producing industrial components, tooling, and molds with high accuracy.

Conclusion

Lathe-turning tools are indispensable in the manufacturing sector, enabling the precise shaping and machining of various materials. Understanding the different types of lathe-turning tools and their applications is crucial for optimizing the performance of lathe machines and achieving desired outcomes in machining processes.

For more insights into industrial tools and machinery, stay tuned to our blog for regular updates and informative articles.