Embark on a journey through the intricate world of machining, where precision meets innovation. Explore the dynamic processes of milling and turning, each with its own distinct essence and capabilities. From the rhythmic dance of rotating cutters to the artistry of shaping raw materials, discover the transformative power of machining.

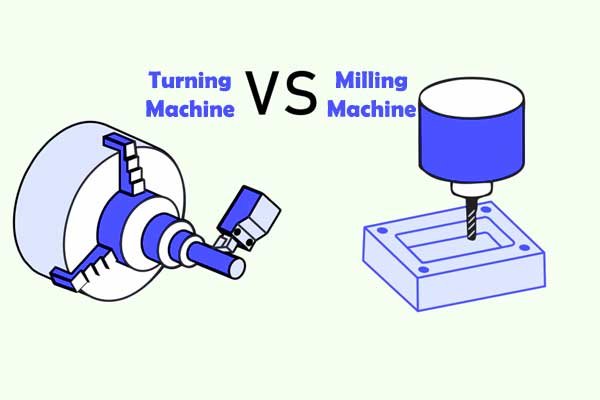

What is Turning?

Turning is a machining process that revolves around rotating a workpiece while a cutting tool traverses along its surface. This rotational motion, typically facilitated by a lathe, enables the creation of cylindrical shapes and intricate contours.

What is Milling?

Contrary to turning, milling involves the use of a rotating cutting tool to carve out material from a stationary workpiece. This subtractive process enables the fabrication of diverse geometries, ranging from simple slots to complex three-dimensional forms.

what is center drill: everything you need to know about center drilling

Understanding the Difference simply:

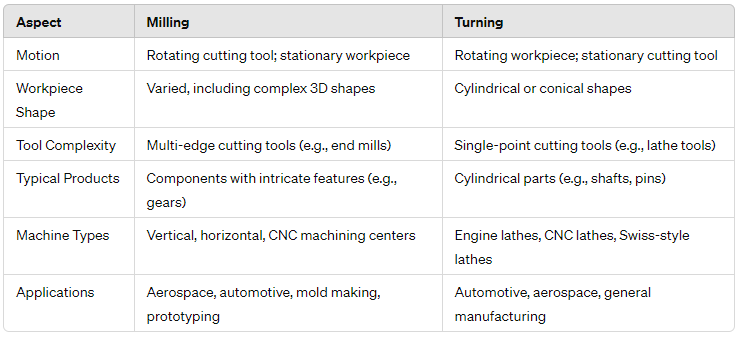

This table provides a quick overview of the key differences between milling and turning in terms of motion, workpiece shape, tool complexity, typical products, machine types, and applications.

Exploring Types and Tools:

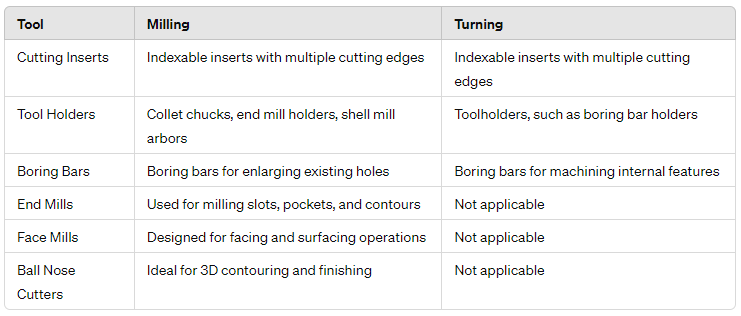

This table outlines the main tools used in milling and turning processes, including cutting inserts, tool holders, boring bars, end mills, face mills, and ball nose cutters.

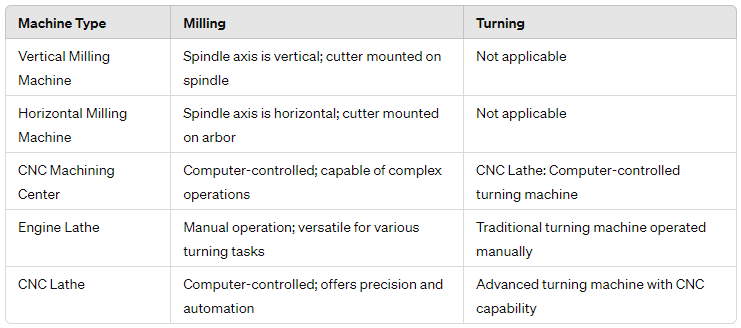

This table highlights the different types of milling and turning machines, including vertical and horizontal milling machines, CNC machining centers, engine lathes, and CNC lathes.

Crafting Precision with Turning and Milling:

Turning and milling stand as pillars of modern manufacturing, each offering unique capabilities and advantages. Whether it’s the rotational finesse of turning or the intricate profiling prowess of milling, these processes converge to sculpt raw materials into refined components, driving innovation across industries.

Crafting impeccable components requires a thorough understanding of turning and milling, from their fundamental principles to the nuances of tool selection and machine operation. By harnessing the synergies between these machining techniques, manufacturers can embark on a journey of precision engineering, delivering solutions that transcend conventional boundaries.

Through meticulous attention to detail and a commitment to excellence, turning and milling continue to shape the landscape of modern manufacturing, propelling industries toward new horizons of innovation and efficiency.

Conclusion:

In the dynamic realm of machining, turning and milling emerge as quintessential techniques, each contributing its unique essence to the art of fabrication. By exploring their intricacies and embracing their divergent paths, manufacturers unlock a realm of possibilities, where raw materials are transformed into works of precision and ingenuity. As the wheels of progress turn and the cutters of innovation mill away, the legacy of turning and milling endures, shaping the future of manufacturing with every revolution and every pass.